CYLINDRICAL GRINDER

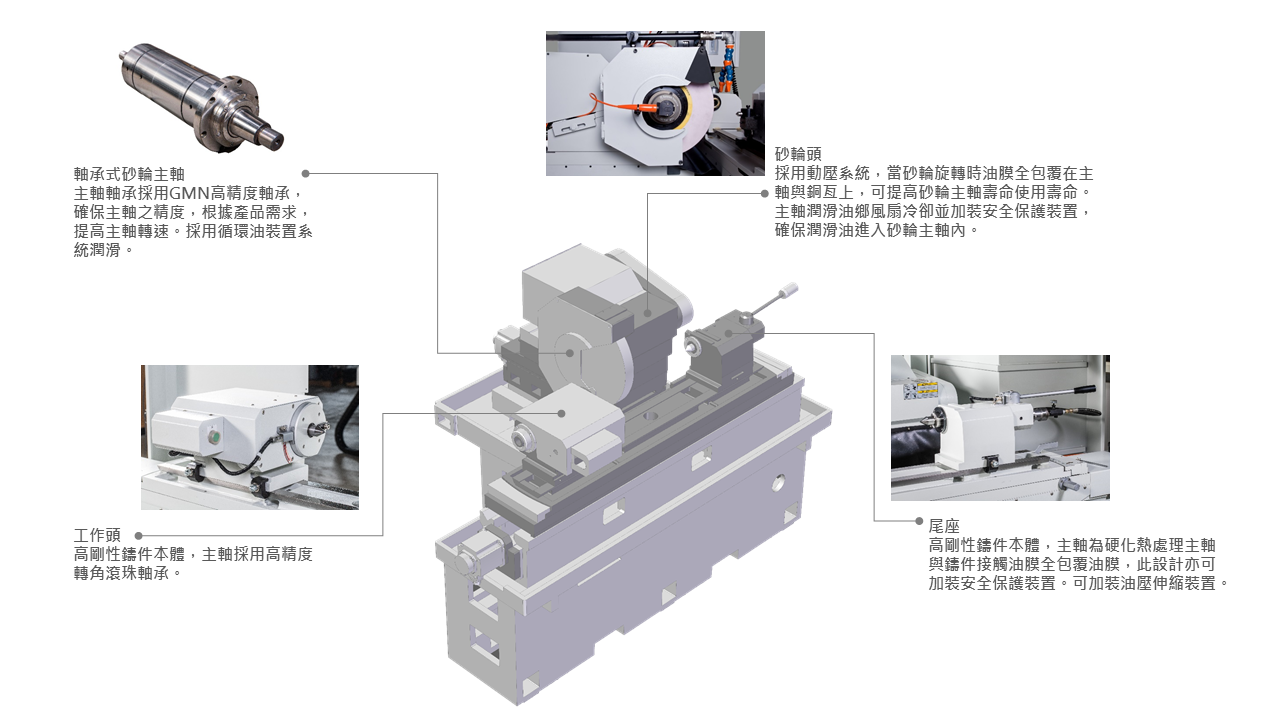

High-rigidity cast machine body, meticulously crafted by skilled artisans, enhances oil film coverage and adopts a continuous lubrication system to extend the lifespan of the bed. The X-axis features a high-rigidity dual-V groove structure with wear-resistant track inserts and continuous lubrication, reducing track wear and ensuring stable motion during axial movement. Grinding Wheel Head Spindle Bearing-type grinding wheel head spindle, equipped with precision GMN bearings, ensures spindle accuracy and allows for increased spindle speed according to product requirements. Lubrication is achieved through a circulating device system. Grinding Wheel Head Utilizes a dynamic pressure system, where the oil film fully envelops the spindle and copper sleeve during wheel rotation, enhancing the lifespan of the grinding wheel head spindle. The spindle lubrication oil tank is equipped with a fan for cooling and additional safety protection to ensure lubrication oil enters the grinding wheel head spindle. Work Head High-rigidity cast body with a spindle featuring high-precision angular contact ball bearings, driven by a servo motor. During the grinding process, it maintains constant torque at a set speed. Tailstock High-rigidity cast body with a spindle that features heat-treated hardening and full oil film coverage upon contact with the casting. It can also be equipped with safety protection devices and hydraulic extension devices. There is also a version with a diameter-inclined head for handling multi-segment complex outer circles and end face cutting.